The Role of Software Integration in Modern Swiss Type CNC Lathes

In contemporary manufacturing, software integration plays a crucial role in enhancing the capabilities of Swiss type CNC lathes. Advanced software systems allow manufacturers to program, monitor, and optimize machining processes with unprecedented precision and efficiency. By combining hardware and software effectively, modern Swiss lathes can achieve higher productivity, improved accuracy, and reduced operational costs.

Enhancing Performance Through Software

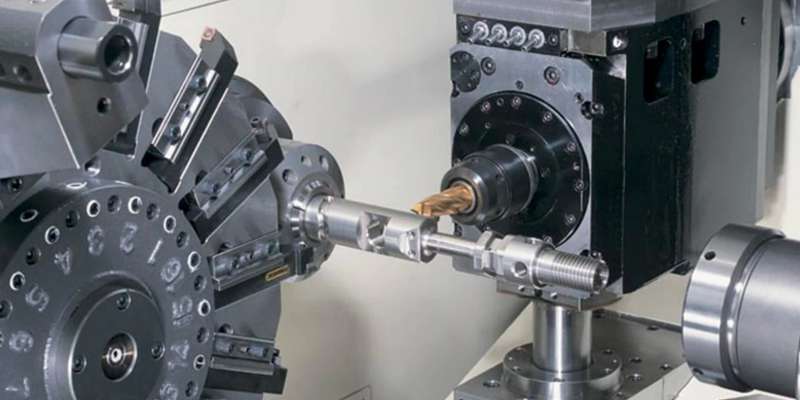

The integration of sophisticated software in a swiss type cnc lathe allows operators to control complex machining operations with ease. Software systems manage multi-axis movements, coordinate tool paths, and optimize cutting parameters in real-time. This capability not only reduces manual intervention but also ensures consistent output across large production runs. Manufacturers benefit from enhanced precision, minimized material waste, and more efficient use of machine resources.

Advanced Programming and Simulation

Modern Swiss type CNC lathes leverage software that supports advanced programming and simulation features. Programmers can create detailed tool paths, simulate machining operations, and identify potential collisions or errors before actual production begins. This pre-production simulation is critical for reducing trial-and-error processes, shortening setup times, and ensuring that components are machined accurately the first time. Software-assisted programming also allows for rapid adjustments, making it easier to handle high-mix, low-volume production without compromising quality.

Real-Time Monitoring and Analytics

Integrated software provides real-time monitoring capabilities that allow operators to track spindle speed, feed rate, tool wear, and machine load. These analytics help in identifying inefficiencies or potential issues early, preventing downtime and costly errors. Some modern systems include predictive maintenance features, alerting operators to required servicing or part replacements before failures occur. By providing insights into machine performance, software integration supports more reliable and uninterrupted production.

Automation and Workflow Optimization

Software integration enables higher levels of automation, which is essential for efficient production. Features such as automated tool changes, multi-part scheduling, and adaptive cutting strategies optimize workflow and reduce manual handling. Operators can program sequences to run unattended for extended periods, allowing Swiss type CNC lathes to produce complex components continuously. This automation increases throughput while maintaining high precision, making the machines suitable for high-volume and high-mix production environments.

Data Management and Connectivity

Modern software systems also facilitate data management and connectivity, allowing Swiss type CNC lathes to communicate with other machines, enterprise resource planning (ERP) systems, and quality control platforms. This connectivity enables centralized monitoring of production lines, streamlined reporting, and faster decision-making. Data-driven insights help manufacturers refine processes, reduce cycle times, and maintain consistent quality across all production batches.

Supporting Operator Efficiency

Software integration enhances operator efficiency by simplifying programming tasks, providing intuitive user interfaces, and offering troubleshooting guidance. Operators can quickly set up new jobs, make adjustments on the fly, and monitor multiple parameters simultaneously. This reduces the learning curve for new personnel and allows skilled operators to focus on process optimization and quality control rather than manual intervention.

Future Trends in Software Integration

The role of software in Swiss type CNC lathes continues to expand with emerging technologies. Artificial intelligence, machine learning, and cloud connectivity are being incorporated to further optimize tool paths, predict maintenance needs, and enhance production efficiency. These advancements promise to make Swiss lathes even more capable of handling complex parts, reducing waste, and adapting to dynamic production requirements.

Conclusion

Software integration is a cornerstone of modern Swiss type CNC lathe performance. By enabling advanced programming, real-time monitoring, automation, data management, and operator support, software enhances precision, efficiency, and reliability. Manufacturers that leverage fully integrated software systems can maximize machine capabilities, reduce operational costs, and maintain high-quality standards. Incorporating software-driven strategies ensures that Swiss type CNC lathes remain adaptable and productive in today’s fast-paced, high-precision manufacturing environment.