Common Mistakes to Avoid When Choosing a Swiss Type CNC Lathe

Selecting the right machine for precision manufacturing is a critical decision that can significantly impact productivity, quality, and operational costs. The Swiss type CNC lathe is highly valued for producing small, intricate components with tight tolerances. However, choosing the wrong model or overlooking key specifications can lead to inefficiencies, increased downtime, and unnecessary expenses. Understanding common mistakes and how to avoid them ensures manufacturers make informed decisions.

Overlooking Machine Precision and Tolerances

One of the most frequent mistakes is failing to assess the machine’s precision capabilities. Swiss type CNC lathes are designed for high accuracy, but not all models offer the same tolerance levels. It is essential to review spindle runout, axis positioning accuracy, and repeatability. Selecting a machine with inadequate precision can result in subpar surface finishes, rejected parts, and additional rework. Manufacturers should carefully match the lathe’s capabilities to the specific tolerances required for their products.

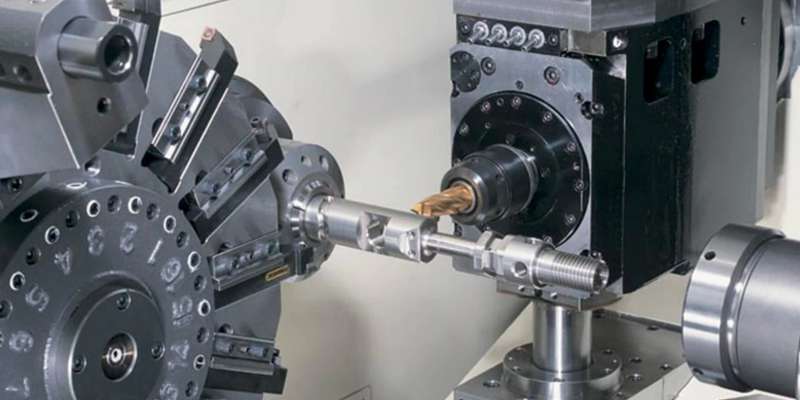

Ignoring Axis Configuration and Multi-Tool Options

Another common error is underestimating the importance of axis configuration and tooling flexibility. Swiss type CNC lathes with more axes and live tooling options enable complex machining operations in a single setup. Failing to consider these features may lead to additional setups, longer cycle times, and higher labor costs. Understanding the component geometries and production volume can help determine the necessary axis configuration and tooling requirements for optimal efficiency.

Focusing Solely on Price

While budget considerations are important, choosing a Swiss type CNC lathe based solely on price can be detrimental. Lower-cost machines may compromise on spindle quality, structural rigidity, or automation features, ultimately reducing productivity and part accuracy. Investing in a reliable, high-quality machine ensures long-term performance, lower maintenance costs, and consistent output. For manufacturers evaluating options, a swiss type cnc lathe provides a balanced combination of precision, durability, and automation to support efficient production.

Neglecting Material Compatibility

Swiss type CNC lathes are used to machine a wide range of materials, including metals and high-performance plastics. Overlooking the lathe’s material handling capabilities can lead to suboptimal performance, increased tool wear, and higher scrap rates. Before selecting a machine, it is important to verify the types of materials it can handle efficiently and whether it offers suitable spindle speeds, torque, and tooling options for those materials.

Underestimating Automation and Workflow Requirements

Modern Swiss type CNC lathes offer automation features such as bar feeders, tool changers, and programmable offsets. Ignoring these capabilities can limit production efficiency and increase reliance on manual operations. Evaluating automation options is crucial for high-volume production, as it allows for continuous operation, consistent tolerances, and reduced operator intervention. Properly integrated automation reduces downtime and enhances overall workflow efficiency.

Overlooking Maintenance and Support

Maintenance requirements and after-sales support are often underestimated during the selection process. Swiss type CNC lathes require routine maintenance to ensure long-term accuracy and reliability. Choosing a machine without considering the availability of service, spare parts, and technical support can result in extended downtime and costly repairs. Manufacturers should ensure the supplier provides comprehensive support and accessible maintenance services.

Ignoring Operator Training and Usability

Even the most advanced Swiss type CNC lathe will not reach its full potential if operators are not properly trained. Overlooking training needs or selecting a machine with a complicated interface can lead to programming errors, inefficient workflows, and reduced production quality. Investing in operator training and choosing a lathe with user-friendly controls ensures smooth operation and maximizes the machine’s capabilities.

Failing to Consider Space and Layout Requirements

Swiss type CNC lathes vary in size and configuration. Neglecting to assess the required floor space and integration into existing production layouts can create logistical challenges. Adequate space for maintenance, bar feeders, and material handling is necessary to maintain efficiency. Planning for installation and workflow integration ensures optimal utilization of the machine without disrupting other operations.

Conclusion

Choosing a Swiss type CNC lathe involves careful consideration of precision, axis configuration, material compatibility, automation, maintenance, and operator training. Avoiding common mistakes such as focusing solely on price, ignoring workflow requirements, or neglecting support ensures that manufacturers select a machine that delivers consistent quality and efficiency. By thoroughly evaluating technical specifications and operational needs, businesses can make informed decisions that enhance productivity, reduce errors, and provide a strong return on investment.