Comparing UV Laser Printers with Other Laser Printing Technologies

Laser printing technologies have evolved significantly over the past few decades, providing manufacturers with a range of options for marking, coding, and engraving products. Among these options, UV laser printers have emerged as a preferred choice in industries requiring high precision, durability, and versatility. Understanding how UV laser printers compare with other laser printing methods is essential for businesses seeking the right solution for their production needs.

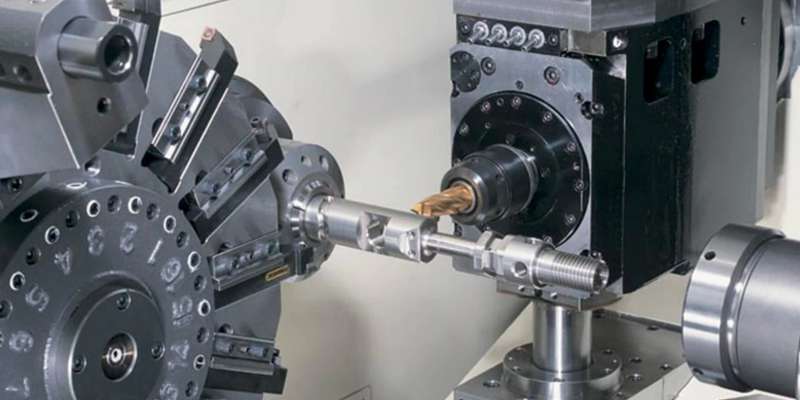

Traditional laser printing technologies, such as CO2 and fiber lasers, have been widely used for marking metals, plastics, and other materials. CO2 lasers are known for their ability to engrave organic materials like wood, paper, and certain plastics, while fiber lasers excel at marking metals and some rigid plastics. Although both technologies offer high-quality results, their applications can be limited depending on the material and the required precision. UV laser printers, on the other hand, use ultraviolet light to create marks by a process called photochemical ablation. This method allows for finer detail and less thermal impact on the material, making it suitable for delicate surfaces and products that are sensitive to heat.

Many manufacturers are now adopting the uv laser printer due to its ability to provide permanent and high-resolution markings on a wide variety of substrates. Unlike CO2 or fiber lasers, UV laser printers minimize heat-affected zones, which prevents material deformation and preserves the integrity of the surface. This capability is particularly advantageous for industries like electronics, pharmaceuticals, and cosmetics, where precision and material integrity are critical.

Material Compatibility and Versatility

A key distinction between UV lasers and other laser types is their broad material compatibility. UV laser printers can mark plastics, glass, metals, ceramics, and coated materials with consistent clarity. CO2 lasers struggle with metals and certain plastics, often requiring coatings to achieve the desired mark. Fiber lasers, while excellent for metals, may not perform well on coated surfaces or transparent materials. By providing reliable performance across diverse substrates, UV laser printers allow manufacturers to streamline operations and reduce the need for multiple printing technologies.

Print Quality and Detail

UV laser printers excel in producing fine, detailed markings that are difficult to replicate with other laser technologies. The short wavelength of UV light enables micron-level precision, making it ideal for creating QR codes, barcodes, and intricate logos. In comparison, CO2 and fiber lasers produce slightly larger marks due to longer wavelengths, which can impact readability and aesthetic quality for very small or detailed designs.

Durability and Longevity

Another significant advantage of UV laser printers is the durability of the markings. The photochemical ablation process ensures that marks are resistant to abrasion, chemicals, and environmental conditions. While fiber lasers can achieve durable markings on metals, UV laser printers provide similar resilience on sensitive surfaces without the risk of surface damage. CO2 lasers, although durable on organic materials, are limited in chemical and abrasion resistance on synthetic products.

Operational Efficiency

UV laser printers also stand out in terms of operational efficiency. They require minimal maintenance, have low power consumption, and do not rely on consumables like inks or solvents. This contrasts with some traditional laser technologies that may involve higher energy usage or additional preparation steps for certain materials. Moreover, the ability to mark multiple materials without changing settings or equipment reduces downtime and enhances production flow.

Applications Across Industries

Industries such as electronics, medical devices, pharmaceuticals, and cosmetics increasingly rely on UV laser printers for compliance, traceability, and branding purposes. Other laser technologies, while still valuable, may require additional equipment or adjustments to achieve similar results. The adaptability of UV lasers makes them a versatile and forward-looking choice for companies aiming to maintain high-quality standards while optimizing production efficiency.

Conclusion

In comparing UV laser printers with other laser printing technologies, it is clear that UV systems offer unique advantages in precision, material versatility, durability, and efficiency. Their ability to produce high-resolution, permanent marks on a wide range of substrates makes them suitable for industries with stringent quality and regulatory requirements. While CO2 and fiber lasers remain effective in specific applications, UV laser printers provide a balanced solution for manufacturers seeking consistent, reliable, and high-quality marking across diverse products.