How a pH Sensor for Water Helps Optimize Chemical Dosing Systems

Chemical dosing systems are a critical part of water treatment processes, ensuring that water is safe for consumption, industrial use, or environmental discharge. Accurate dosing of chemicals such as coagulants, disinfectants, and pH adjusters depends on precise measurements of water chemistry. Among the most important parameters for controlling these systems is pH, which directly influences chemical reactions and treatment efficiency.

Integrating a reliable pH monitoring solution allows operators to adjust chemical dosing in real time, preventing under- or over-treatment. Fluctuations in pH can impact coagulation, precipitation, and disinfection processes, potentially compromising water quality. Continuous monitoring ensures that chemical addition is optimized, maintaining water quality while minimizing waste and operational costs.

Using a pH Sensor for Water provides accurate and continuous pH data that supports automated dosing systems. By delivering real-time information, these sensors enable precise control of chemical injection, reducing the risk of overdosing or underdosing. This improves treatment efficiency, reduces chemical consumption, and ensures compliance with regulatory standards.

The Role of pH in Chemical Dosing

pH is a measure of the acidity or alkalinity of water and affects the performance of chemicals used in treatment processes. For instance, coagulants and flocculants require specific pH ranges to function effectively. Similarly, disinfectants such as chlorine have optimal efficacy at certain pH levels. If the pH drifts outside the desired range, chemical reactions may be inefficient, resulting in poor water quality or higher chemical consumption.

Accurate pH monitoring allows operators to fine-tune chemical dosing, ensuring that treatment processes operate at peak efficiency. By maintaining the correct pH, water treatment facilities can achieve desired water quality outcomes while reducing costs associated with excessive chemical use.

Real-Time Monitoring and Automation

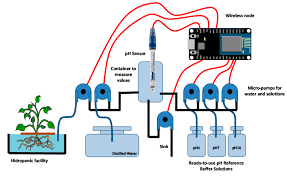

Modern chemical dosing systems often integrate pH sensors with automated controllers. These controllers adjust chemical injection rates based on continuous pH readings, providing precise dosing without manual intervention. Real-time feedback allows the system to respond immediately to fluctuations in water chemistry, improving consistency and reliability.

High-quality pH sensors offer rapid response times, enabling quick adjustments to dosing systems. This responsiveness is particularly important in systems dealing with variable water sources, such as surface water affected by rainfall or industrial discharge, where chemical demand can change rapidly.

Enhancing Operational Efficiency

Optimizing chemical dosing with accurate pH data has multiple operational benefits. Reducing chemical overuse lowers operating costs, decreases the formation of harmful byproducts, and minimizes environmental impact. Under-dosing, on the other hand, can compromise water quality and lead to regulatory violations. Continuous pH monitoring ensures that dosing remains within the optimal range, balancing performance, cost, and compliance.

Additionally, sensors reduce the need for frequent manual sampling and laboratory analysis, saving time and resources while maintaining high accuracy.

Maintenance and Sensor Reliability

The effectiveness of chemical dosing optimization relies on the reliability of pH sensors. Regular calibration, proper storage, and routine cleaning are essential to maintain sensor performance. Many modern sensors are designed to resist fouling, corrosion, and temperature fluctuations, ensuring consistent operation even in challenging water conditions.

High-quality sensors also include diagnostic features, alerting operators when maintenance or recalibration is required. This proactive approach reduces downtime and ensures that dosing systems continue to function efficiently.

Integration with Data Management Systems

Many modern pH sensors are compatible with data logging and remote monitoring systems. Integration with Supervisory Control and Data Acquisition (SCADA) or other management platforms allows operators to track pH trends, optimize dosing schedules, and generate reports for compliance and operational analysis.

By combining real-time data with historical trends, facilities can refine chemical dosing strategies over time, further improving efficiency and reducing costs.

Environmental and Regulatory Benefits

Accurate chemical dosing supported by pH monitoring helps facilities comply with water quality regulations. Proper dosing minimizes chemical residues in treated water, reduces environmental impact, and ensures that discharged water meets regulatory standards. Continuous monitoring also provides verifiable documentation for reporting purposes.

Conclusion

A pH Sensor for Water plays a vital role in optimizing chemical dosing systems by providing accurate, real-time pH measurements. Integration of these sensors ensures precise chemical application, enhances operational efficiency, reduces costs, and supports regulatory compliance. By leveraging high-quality pH sensors, water treatment facilities can maintain consistent water quality, improve sustainability, and achieve reliable performance across various treatment processes.